Are you looking for a quick and easy way to join pipes without welding? Do you want to make tubular structures precisely and easily? Not sure how you can connect metal pipes without threading or using a welding machine? See how to connect steel pipes without welding and thread! Find out what weldless pipe fittings are! Discover the use and advantages of using Klemp connectors!

How to connect steel pipes without welding?

There are several ways to connect pipes without welding, among them you can connect pipes by threading or using pipe fittings. However, the simplest and easiest way will be to use Klemp pipe fittings. Such pipe connections allow for a tight connection without threading and welding. This makes it easy for anyone to connect any structure without the need for special tools.

What are metal pipe fittings?

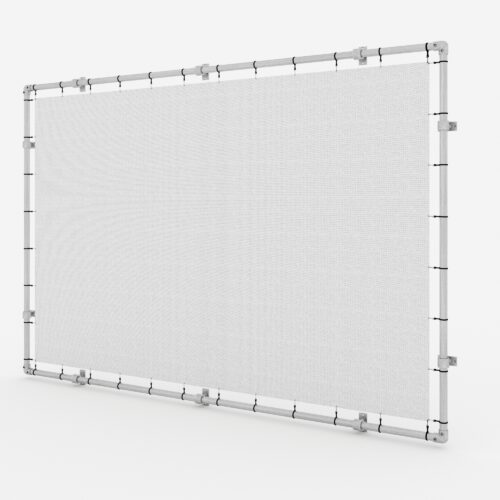

Weldless pipe fittings are pipe fittings that you can use to install tubular structures. Pipe connectors are made of cast iron with a layer of zinc applied, thanks to which the connectors are resistant to damage or adverse weather conditions. What’s more, the seamless joints were created by pouring the entire metal alloy into the appropriate molds, which allowed to obtain monolithic shapes resistant to heavy loads.

What are the applications of weldless pipe joints?

You can use seamless pipe joints in many ways. They will work equally well at home and in the garden, garage or workshop. You can use seamless methods to build security and other types of structures that will facilitate your work and everyday functioning. You can use metal pipe joints without welding to build:

- railings,

- hangers,

- construction of pipes in water installations,

- shelving,

- workshop trolleys,

- pergola,

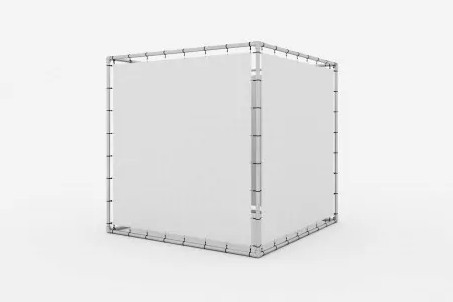

- box construction,

- furniture,

- garden seats.

What’s more, the use of weldless joints gives a reliable connection of the pipes, which allows for easy disassembly if necessary.

Advantages of using fasteners – wide possibilities

The use of cast iron joints to connect metal pipes gives us the opportunity to create various and durable structures. One of the key advantages is that with pipe joints you can connect metal pipes without welding, all you need is a set of appropriate pressure screws and an Allen key. This makes repairing and assembling projects very easy. In addition, thanks to the additional protection against corrosion, you can be sure that the use of connectors will work both inside and outside buildings.

How much do weldless fittings cost?

The price of fittings may vary depending on the type of seamless fitting. You can buy Klemp pipe connectors from just a few zlotys a piece. Usually the price ranges from PLN 10 to PLN 200, depending on the type of connectors. What’s more, the price is also affected by the type and color of the connector. You can choose from square, round and black connectors, which will perfectly match the industrial decor.

Summary

- If you want to connect steel pipes without welding, you can use threading or weldless pipe fittings.

- While threading is a more difficult form of connecting pipe structures, weldless joints enable easy and precise assembly of steel or aluminum pipes.

- Seamless fittings are pipe fittings that you can use to install various pipe structures. Solid connectors are made of high-quality cast iron, which has been cast into appropriate molds, making the connector durable and resistant to loads.

- The fasteners are covered with a protective layer of zinc, which prevents corrosion and adverse weather conditions.

- There are many ways to use seamless pipe connections. With the help of connectors, you can make a variety of projects for the interior of the house, workshop, garage or basement. In addition, thanks to the protective cover, the connectors can be used for external constructions.

- Using pipe connections, you can make shelves, shelves, tables, seats, pergolas, elements of playgrounds, railings and safety barriers.

- The biggest advantage of using pipe fittings is easy and quick assembly. To connect the pipes with connectors, all you need is an Allen key and pressure screws. You don’t have to learn welding and have the right tools for it.

- By using seamless fittings, you can easily complete any project and piping installation.

- By choosing to connect pipes using the non-welding method, you save a lot of time and resources that would have been spent on learning welding and the appropriate equipment. What’s more, you can choose from many types of pipe fittings, which means that no design limits you.

- If necessary, you can quickly disassemble the pipes connected by the weldless method, and the unscrewed elements can be reassembled in the future.

FAQ

Weldless pipe fittings are special fittings into which pipes are inserted and then tightened with pressure screws. The joints are made of cast iron and covered with a layer of zinc, which makes them resistant to loads and adverse weather conditions. Properly selected connectors have clamping rings with a suitable gasket.

Pipe connectors can be used to build any type of steel pipe structure. Many types of seamless fittings make it possible to perform various steel projects thanks to them. Most often, pipe connectors are used to build furniture, including shelves, tables, seats or shelves. They can also be used as elements of hangers, workshop shelves, pergolas, elements of playgrounds, racks for weights in the gym.

Seamless pipe joints are one of the simplest methods of joining pipes. For assembly, you only need clamping screws that press the screw to the nut and an Allen key to tighten the screws. After assembly, the structure will be ready for use – you do not need to additionally seal it.