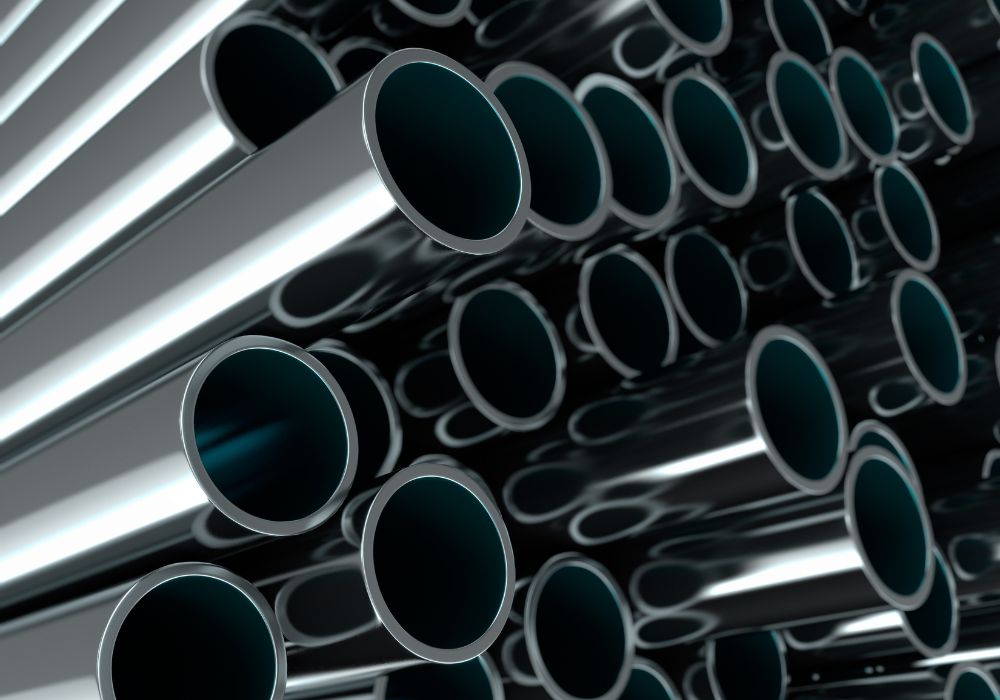

Aluminum pipes are one of the most important components in many industrial sectors. Whether you are an engineer, designer or simply someone interested in technology and materials, the following article will provide you with a comprehensive knowledge of them.

We have prepared a comprehensive overview containing everything you need to know about aluminum pipes. We will focus on their characteristics, types, production process and applications We will also suggest what to pay attention to when choosing the right aluminum pipes.

Aluminum pipes – one of the most common elements in the industry

Aluminum pipes are one of the most versatile and widely used components in many industry sectors. Thanks to their unique properties such as lightness, corrosion resistance, good thermal and electrical conductivity, as well as the ability to form into various shapes, aluminum pipes have become irreplaceable in many sectors.

Their versatility makes them an inseparable element in such diverse fields as construction, automotive, aerospace, energy or chemicals. In construction, aluminum pipes are often used in structures such as window frames, doors, building facades, as well as in ventilation and air conditioning systems. In the automotive and aerospace industries, due to their lightness and strength, they are irreplaceable in the production of various types of vehicles and machines.

Aluminum pipes are also a key component in the power industry, where their excellent thermal and electrical conductivity is essential. In the chemical industry, aluminum pipes are used in transmission systems, where their corrosion resistance is crucial.

Various shapes and sizes of aluminum pipes

Aluminum pipes are available in a variety of shapes and sizes, which makes them extremely flexible. They can be round, square or rectangular and their size can be adapted to the specific requirements of a given project. Round aluminum tubes are most commonly used because of their versatility, but square and rectangular tubes are often used where greater strength or a specific shape is required. Regardless of the shape or size, aluminum pipes always offer excellent strength and durability, making them an ideal choice for many industrial applications.

Aluminium pipes – characteristics

Due to their unique properties, aluminum pipes are one of the most important materials used in many industry sectors. Below are detailed characteristics of these extremely versatile components.

Properties and benefits of aluminum pipes

Aluminum pipes, known for their lightness, are easy to transport and install, which is one of their key advantages. Despite their low weight, they are characterized by extraordinary strength and corrosion resistance, which guarantees their long service life.

One of the most important advantages of aluminum pipes is their excellent thermal and electrical conductivity. This feature makes them an excellent choice for applications that require efficient conduction of heat or electric current.

Aluminum tubes are also easy to form and weld, which makes it possible to create intricate shapes and structures. This flexibility allows them to be used in a wide range of projects, from simple constructions to more complex structures.

In addition, aluminum pipes are available in a variety of alloys that offer multiple properties such as increased strength, better corrosion resistance, and better thermal and electrical conductivity. This allows the pipes to be adapted to the specific requirements of a given project, making them even more versatile.

Alloys used in the manufacture of aluminum tubes

Aluminum pipes are usually manufactured from various aluminum alloys, which give them additional properties. The most commonly used alloys are 2024, 3003, 6061, 5052 and 7075. Each of these alloys has its own unique properties that result from the addition of other metals such as copper, manganese, zinc, magnesium and silicon.

Alloy 2024 is an aluminum alloy with the addition of copper. It is a high-strength alloy, often used in the aerospace and automotive industries, where high strength while maintaining low weight is required.

Alloy 3003 is an aluminum alloy with the addition of manganese. It is an alloy with good corrosion resistance and excellent weldability, making it an ideal choice for applications that require forming and welding, such as building structures or ventilation systems.

Alloy 6061 is an aluminum alloy with the addition of magnesium and silicon. It is easy to weld and naturally corrosion resistant, making it an ideal choice for many applications, including structures, industrial pipes, and bicycles.

Alloy 5052 is an aluminum alloy with the addition of magnesium. It is an alloy with excellent corrosion resistance, especially in marine and brine environments, so it is used in the marine and chemical industries.

Alloy 7075 is an aluminum alloy with the addition of zinc. It is a very high strength alloy, often used in the aerospace and automotive industries, where high strength while maintaining low weight is required.

Comparison of aluminum pipes with steel pipes

Although steel pipes are also widely used in many industry sectors, aluminum tubes have several advantages that make them a more attractive choice in many applications. First of all, aluminum pipes are much lighter than steel pipes, which makes them easier to transport and install.

In addition, aluminum pipes are naturally resistant to corrosion, which means that they do not require additional corrosion protection as in the case of steel pipes. Aluminum tubes are also more flexible and easier to mold than steel tubes, allowing creating more complex shapes and structures.

Finally, aluminum tubes have better thermal and electrical conductivity than steel tubes, making them a perfect choice for applications that require efficient heat or electric conduction.

Aluminium pipes – types

Aluminum tubes are available in a variety of shapes and sizes, which makes them versatile. Below are the three main types of aluminum pipes.

Round aluminum pipes

Round aluminum tubes are the most commonly used type of aluminum tubes, thanks to their versatility and ease of processing. They are used in many industrial sectors, from construction, through the bicycle industry, to the aviation industry. Their round shape makes them easy to form and weld, which makes it possible to create complex shapes and structures. In addition, round aluminum tubes are very durable and resistant to corrosion, which translates into their long service life. Their lightness and durability make them an ideal choice for many applications.

Square aluminum pipes

Square aluminum pipes are often used where greater strength or a specific shape is required. They are often used in structures such as window frames, doors, as well as in the manufacture of furniture. Their square shape provides greater strength and rigidity, which is especially important in supporting structures. Square aluminum tubes are easy to cut and weld, which makes it possible to create precise shapes and structures.

Rectangular aluminum pipes

Rectangular aluminum pipes are ideal for applications that require greater strength and rigidity. They are often used in structures such as window frames, doors, as well as in the manufacture of furniture. Their rectangular shape provides additional strength and rigidity, which is especially important in supporting structures. Rectangular shaped aluminum tubes can be easily cut and welded, which allows you to form accurate shapes and structures.

Regardless of the shape, all pipes are resistant to corrosion, which guarantees a long service life of these components.

Production of aluminium tubes

The production of aluminum pipes is a complex process that requires precise control and experience. This process consists of two main steps: aluminum extrusion and finishing, and heat treatment.

Aluminum extrusion process

Aluminum extrusion is the first stage of aluminum pipe production. This process involves heating the aluminum alloy to the right temperature and then pressing it through a matrix that gives it the desired shape. The die can have different shapes, depending on the requirements of a particular project, which allows the production of pipes of various shapes, such as round, square or rectangular.

Finishing and heat treatment process of aluminum pipes

After the extrusion process, aluminum pipes are subjected to a finishing and heat treatment process. The finishing process can include cutting pipes to the right length, cleaning the surface, as well as painting, anodizing or coating, depending on the requirements of the specific application.

Heat treatment, in turn, involves heating the pipes to a certain temperature and then cooling, which improves their mechanical properties, such as strength and hardness. This process is necessary to ensure that the final aluminum pipes meet all requirements and quality standards.

The entire aluminum tube production process requires precise control and experience to ensure that the ready-to-use product meets all requirements and quality standards.

Application of aluminum pipes

Aluminium tubes are extremely versatile and are used in many industrial sectors. Here are some examples:

Construction & Architecture

In construction, aluminum pipes are often used in structures such as window frames, doors, building facades, as well as in ventilation and air conditioning systems. Thanks to their corrosion resistance, they are ideal for outdoor applications where they are exposed to weather conditions.

Furniture industry

In the furniture industry, aluminum tubes are used in the manufacture of various types of furniture, from tables and chairs, to cabinets and shelves. Thanks to their lightness and strength, they are ideal for the manufacture of furniture that must be both durable and easy to move.

Bicycle industry

In the bicycle industry, aluminum tubes are a key component of bicycle frames. Thanks to their lightness and durability, they allow the production of lightweight and durable bicycles that are at the same time easy to control and comfortable to use.

Automotive

In the automotive industry, aluminum tubes are used in many components, from vehicle frames to cooling systems to interior trim. Thanks to their lightweightness, they help to reduce the weight of the vehicle, which translates into better fuel efficiency.

Aerospace

In the aerospace industry, aluminum tubes are irreplaceable due to their high strength and low weight. They are used in many aircraft components, from the fuselage structure, through hydraulic systems, to interior elements.

Energy industry

In the power industry, aluminum pipes are often used in transmission systems where their good electrical conductivity is essential. They are also used in wind turbine constructions, where their lightness and strength are crucial.

Chemical & Pharmaceutical

In the chemical and pharmaceutical industries, aluminum pipes are used in transmission systems, where their corrosion resistance is extremely important. They are also used in the production of laboratory equipment, where their next feature, which is the ease of cleaning, is checked.

How to choose aluminum pipes?

Choosing the right aluminum pipes is crucial for the success of a given project. Below are some criteria that are worth considering when choosing aluminum pipes.

Criteria for the selection of aluminum pipes

When choosing aluminum pipes, one of the most important criteria is their purpose. Different applications may require different properties such as strength, corrosion resistance, thermal and electrical conductivity, as well as shape and size.

Another important criterion is the type of aluminum alloy from which the pipes are made. Different alloys have different properties that can be better or worse adapted to a specific application, as we wrote above.

Different characteristics of aluminum pipes

Aluminum pipes have many characteristics that can affect their suitability for a particular application. For example, their shape and size can affect their strength and ability to carry loads. Their thermal and electrical conductivity can be important in applications that require efficient conduction of heat or electric current. Corrosion resistance, on the other hand, can be crucial in applications that require prolonged exposure to moisture or chemicals.

In conclusion, choosing the right aluminum pipes requires careful consideration of many factors, including their purpose, the properties of the alloy, as well as various characteristics that can affect their suitability for a particular application.

Advantages of using aluminum tubes

Aluminum tubes offer many advantages that make them an ideal choice for many applications. Below are a few of them.

Longevity and corrosion resistance

One of the most important advantages of aluminum pipes is their longevity. Thanks to their natural corrosion resistance, aluminum pipes can last for many years without significant deterioration, even in harsh weather conditions or when exposed to aggressive chemicals. This makes them an ideal choice for outdoor applications such as building structures, as well as for applications in the chemical and pharmaceutical industries.

Lightness and good thermal and electrical conductivity

Another important advantage of aluminum pipes is their lightness. They are much lighter than steel pipes, which makes them easy to transport and install. Despite their lightness, aluminum tubes are extremely durable, making them ideal for applications that require both lightness and strength.

In addition, aluminum tubes are characterized by excellent thermal and electrical conductivity. This makes them irreplaceable in applications requiring efficient heat or electric conduction. Hence, they are often used in cooling systems, in the energy industry, as well as in the production of electronic equipment.

Aluminium pipes – summary

Aluminum pipes are an extremely versatile material that is used in many industrial sectors, from construction, through furniture, bicycles, automotive, to energy, chemical and pharmaceutical industries. Thanks to their unique properties such as lightness, strength, corrosion resistance and excellent thermal and electrical conductivity, aluminum tubes are irreplaceable in many applications.

Choosing the right aluminum pipes depends on many factors, such as their purpose, alloy properties, as well as various characteristics that can affect their suitability for a particular application. Aluminum tubes offer many advantages such as longevity, corrosion resistance, lightness and good thermal conductivity.