The table is one of the most common constructions made of round tubes. Its advantage is that thanks to the appropriate selection of the colour of pipes and connectors, we are able to build both a fashionable industrial-style piece of furniture for a properly arranged living room or dining room, and even a kitchen, as well as a model suitable for placing on the terrace or in the garden. Making a table out of structural pipes is not a difficult task if we think about its appearance and functionality in advance, create a project and calculate the length of individual elements.

FIRST – DETERMINING THE PURPOSE OF THE TABLE

Whether our planned table will become part of the apartment’s furnishing or will serve us outside the house, largely determines the colour of the steel elements that we will use for its construction. If we care about loft-style furniture, we advise you to opt for the black colour of pipes and connectors, while for the kitchen, dining room or garden, we suggest using galvanized steel. Below, a few words about black and galvanized coatings.

Black pipes and fittings owe their colour to cataphoresis – modern paint technology used to protect objects made of metal against corrosion. It consists in immersion painting with simultaneous current flow through the paint solution. Paint particles are lifted in accordance with the polarity of the electromagnetic field and settle on the surface of the detail. The great advantage of this technology is that painting is effective also in places that would be difficult to reach using traditional methods. The obtained coating meets very high resistance requirements and is characterized by remarkable aesthetic values.

Galvanized pipes and fittings are immediately recognizable because they are glossy and silver in colour. The process of obtaining such a coating consists of several stages. At the beginning, operations related to the preparation of the surface for the application of the zinc layer take place. It is mechanical and chemical cleaning to get rid of grease and casting impurities, followed by preparatory baths. The galvanizing process itself consists in immersing the details in a bath of molten zinc at a temperature of 445°C – 455°C. By diffusion, i.e., the penetration of zinc atoms into the outer layer of steel, a surface iron-zinc alloy is formed. The coating obtained in this way, after cooling in water, is characterized by high mechanical resistance and aesthetic appearance.

TABLE SIZE

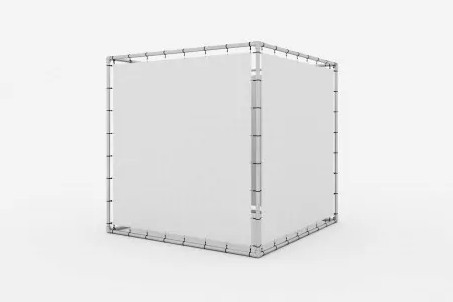

The advantage of making the table yourself from pipes and steel connectors is complete freedom in determining its size. Of course, the matter gets a bit more complicated when we wanted to create a piece of furniture with a large, unusual size of the top, which will need additional support points. However, in the case of a standard-sized piece of furniture, the design is simple. For the purposes of this article, we will discuss how to create a galvanized steel table, based on a model of one of the ready-made tables offered by our store. Although the prototype was built of aluminium pipes, we,

however, in order to reduce costs, propose the use of steel pipes. The table has dimensions of 200 x 100 x 80 cm, which you can freely change during the design process.

ELEMENTS NECESSARY FOR BUILDING THE FRAME

- Single-socket tee – 42.4 mm – 6 pcs. This fitting is used to connect the lower stiffening elements: two shorter ones, each of which connects two adjacent table legs and one with the length of the entire frame.

- Wall connector – round foot – 42.4 mm – 4 pcs. These connectors are the feet of the table legs.

- Corner elbow 90° – 42.4 mm – 4 pcs. Each of these elbows connects three pipe sections: the table leg and two frame elements under the table top.

- Handle with a single eye – 42.4 mm – 10 pcs. With these handles, we will attach the top to the table structure.

- Galvanized steel pipe – Ø 42.4 mm x 2.6 mm in sections:

- table legs – 4 pcs.

- short structural sections – 4 pcs.

- long structural sections – 3 pcs.

HELPFUL TIPS

Pipe Diameter:

Most of the tables are made of a pipe with a diameter of 42.4 mm. A pipe diameter of 33.7 mm is also possible, depending on the rigidity of the structure. Then you have to remember to change the diameter of the connectors.

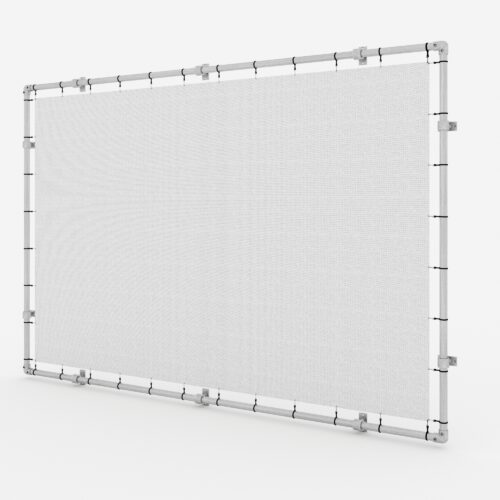

Table top:

The worktop should be made of board or planks of sufficient thickness and large enough to be screwed down using single-eye lugs.

Wheels:

If you want to build a mobile table, you can use castors instead of feet.

How to calculate the pipe length?

In order to create a good design, you should measure the length of the individual tubular elements. The essential thing here is the information about how much of the pipe will go into the fitting. Two pipes meet face-to-face or at a certain angle. The length of the section that is hidden in the connector depends on the shape and characteristics of the section. In each fitting card you will find a table and sectional drawings to help you calculate this length.