Round Tubefittings

Long Slope Tee - Variable angle 0° - 11° Typ 4SC, 33,7 mm , Galvanized

Long Slope Tee - Variable angle 0° - 11° Typ 4SD, 42,4 mm, Galvanized

Long Slope Tee - Variable angle 0° - 11° Typ 4SE, 48,3 mm, Galvanized

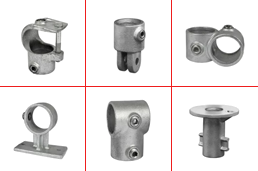

ROUND GALVANIZED PIPE CONNECTORS

TUBE ROUND CONNECTORS - PERFECT QUALITY AND HIGH AESTHETICS

The Klemp system circular connectors offered by us are characterized by the quality ensured by the perfect execution of a high-class coating, which not only creates an elegant product design, but also provides protection against mechanical damage and the effects of unfavorable weather conditions. Galvanized circular connectors are used in almost all types of industrial, protective or indoor structures, such as furniture, patio and garden equipment, creating places for recreation and biological regeneration.

FITTINGS FOR ROUND PIPES - QUICK ASSEMBLY AND DEMOLITION

Connectors for round pipes is an offer that currently includes several dozen types of fittings that allow you to build almost any structure of galvanized steel pipes. An allen screw integrated with them makes installation quick and requires no special qualifications. It is enough to insert the end of the pipe into the connector socket and tighten the screw. Nothing more is needed to make it permanently attached and make it a solid structure.

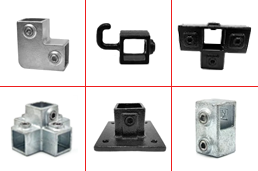

Connectors for round pipes are part of the Klemp system, which includes black painted, galvanized and aluminum connectors and pipes. These elements have common features:

- mutual compatibility,

- easy to connect,

- possibility of disassembly for further use.

ADVANTAGES OF THE KLEMP SYSTEM

When creating the Klemp system, the manufacturer was guided by the principle of quick and easy joining of steel and aluminum pipes into structures of any degree of complexity and the possibility of their disassembly to be used for other projects.

The frequently used techniques for joining pipe structures have two major disadvantages:

- in threaded connections - pipes must be delivered in a strictly defined size and have practically no flexibility in assembly,

- for welded joints - the work of qualified personnel and the use of specialized equipment are required.

Connectors for round tubes, just like other KlempSystem couplings, are equipped with sockets of the appropriate diameter, into which the end of the tube is inserted and locked with a set screw. Such a connection is extremely strong and stable and allows for easy disassembly of the structure if necessary. Thanks to the Klemp system, pipes and couplings can be used multiple times for a variety of projects.

Due to their repeated use and for the sake of maximum safety, clamping screws are subjected to hardening.

ROUND CONNECTORS IN OUR STORE

Galvanized circular connectors are available in six diameters: 21.3mm, 26.9mm, 33.7mm, 42.4mm, 48.3mm and 60.3mm. We divided them into types in terms of their function. In the table below, we have shown the most important of them and given the number of versions available in individual diameters.

Example: corner bends with a diameter of 21.3 mm are only available as a corner tee, while in the group of connectors with a diameter of 26.9 mm there are the following versions: corner tee and adjustable corner tee.

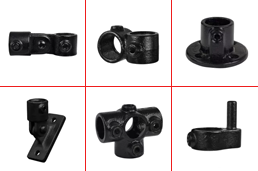

HOW ARE FITTINGS FOR ROUND PIPES MADE?

All KlempSystem fittings for round tubes are manufactured using modern casting technology. Patterns of fittings made by professional modelers are used to build molds for high-pressure automatic molding lines. Iron is melted in electric induction furnaces. During this process, the manufacturer carries out qualitative tests and metallurgical analyzes.

The coupler castings are heat treated to improve toughness and shot blasted to obtain a good surface finish.

ROUND JOINTS - HOT GALVANIZING

Circular joints are fed to the hot dip galvanizing process. which consists of several preliminary operations:

- Abrasive blasting, which consists in the mechanical removal of inhomogeneities in the surface of a galvanized pipe.

- Degreasing and etching with hydrochloric acid bath.

- Fluxing - raw pipes are immersed in an aqueous solution of zinc chloride and ammonium chloride to ensure proper galvanization.

- Drying at 120 ° C-150 ° C.

Round joints, after passing the preliminary stages, are subjected to galvanization. It consists in immersing the fittings in a bath of molten zinc at a temperature of 445 ° C-455 ° C. Under these conditions, a surface iron-zinc alloy is formed by diffusion, i.e. the penetration of zinc atoms into the outer steel layer. The coating of the circular joint obtained in this way, after cooling in water, is characterized by high mechanical resistance and an aesthetic appearance.

TÜV CERTIFICATE

Klemp system round pipe fittings are TÜV-certified. The TÜV quality mark confirms that this product meets the quality requirements, is safe and environmentally friendly.